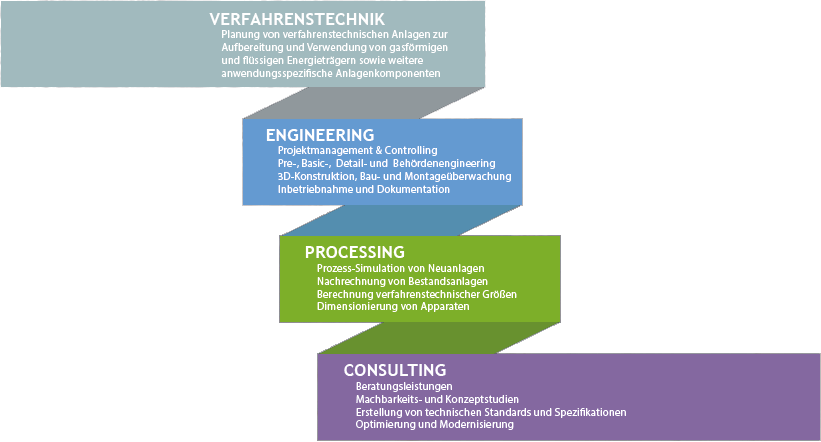

CONSTRUCTION

Our design work is always carried out in 3D and with established software products:

– Autodesk Plant Design Suite©

– Autodesk AutoCAD© including CADISON database attachment©

– Microstation Bentley©

With the Autodesk Plant Design Suite software package, we use an integrated solution with control and verification mechanisms for all modules used. Steel construction and piping designs can be optimized by means of clash detection. Between 3D and P&ID flowcharts, a permanent consistency check prevents different revision levels and statuses. Databases that are easy to create and operate facilitate the creation of pipe classes and standardized components such as apparatus and equipment.

The finished 3D model can be visualized almost photo-realistically, virtual walks through the plant can be carried out using 3D reviews with the customers and rendered presentations can also be generated for project presentations.

SOFTWARE TOOLS

We have the latest software solutions for process simulation and process engineering design of apparatuses. In addition to internationally recognized solutions, we also use our own programs.

We create our designs with 3D planning tools on the basis of various software platforms, our piping and strength calculation programs are officially recognized by the Notified Bodies.

MECHANICS

Mechanical components such as pipelines, apparatus and vessels are specifically adapted by us to the field of application and calculated for internal strength for the required operating conditions. In order to guarantee acceptance by the Notified Bodies at any time, we use TÜV Nord AG own calculation program DIMy©, a dimensioning software for pressure equipment with an integrated material database.

Complex pipeline constructions are checked with the CAE system ROHR2 for static and dynamic analysis. With this software for structural analysis piping systems and connected apparatuses can be examined for excessive stresses. Via the corresponding software interfaces the 3D models created in the design department can be directly imported into ROHR2 and analysed. This calculation program is also accepted by the Notified Bodies as standard for stress calculation.

PROCESS ENGINEERING

We work with the Engineering Suite from AspenTech©, which covers our expertise in process simulation. With the help of this comprehensive software package, we are able to model, simulate and design a wide range of process engineering plants from various branches of industry.

With the energy optimization tool Aspen Energy Analyzer© we can perform pinch analyses and create an optimized heat utilization concept for each process plant.

In addition to the proven programs for process simulation with HYSYS© and the design of shell-and-tube heat exchangers, we supplement our process engineering with the design of

apparatuses such as

– Air coolers & plate heat exchangers

– Precipitators and separators

– Fixed bed reactors for adsorptive processes

With Aspen Plus©, the extensive substance database and various calculation models, we can simulate further chemical and thermodynamic processes:

– Physical & chemical scrubbers

– Chemical reactors (stirred reactors, tube reactors)

– Combustion calculations (flares, combustion chambers, gas turbines, engines)

– air conditioning, refrigeration systems

With HYSYS Dynamics© complete process engineering plants with control of different process parameters can be dynamically simulated under discontinuous entry conditions.